Send Inquiry

Contact Info

-

Address

Zhai Zhuang Road, Hangji Town, Yangzhou City, Jiangsu Province, China

-

Tel

-

E-mail

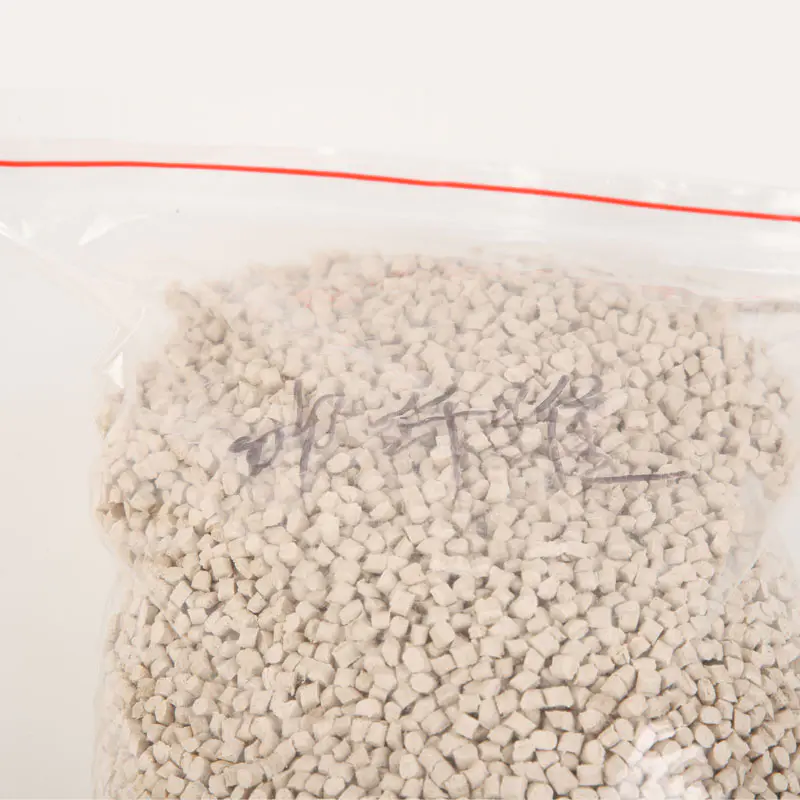

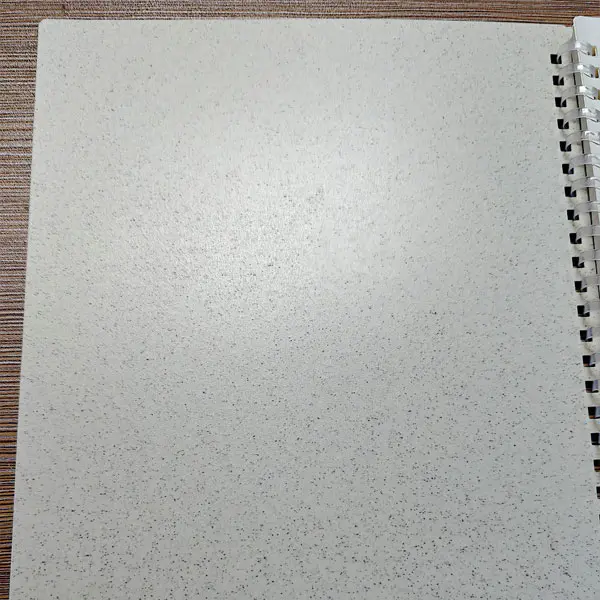

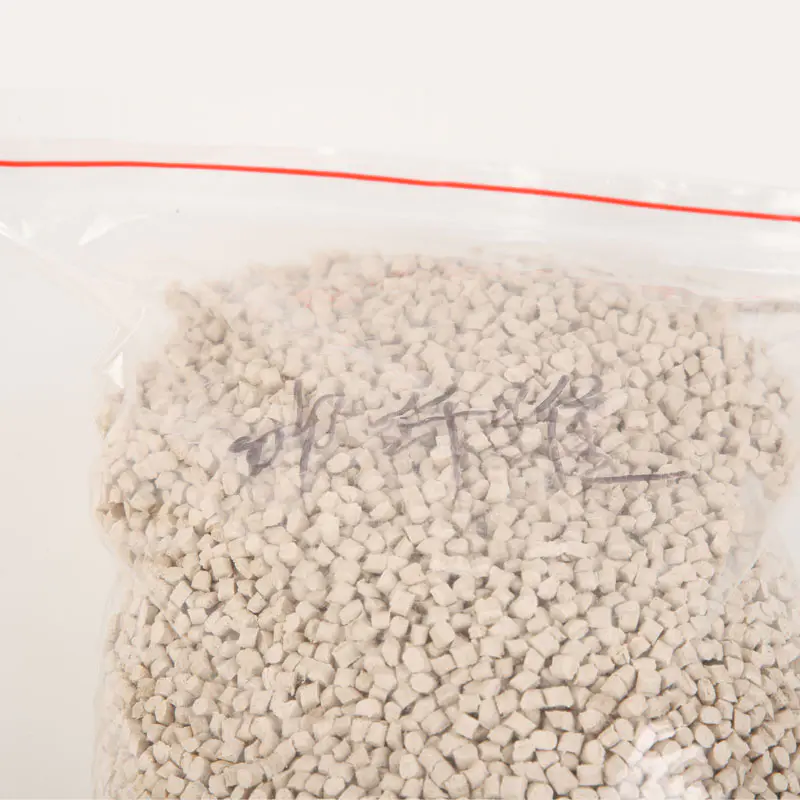

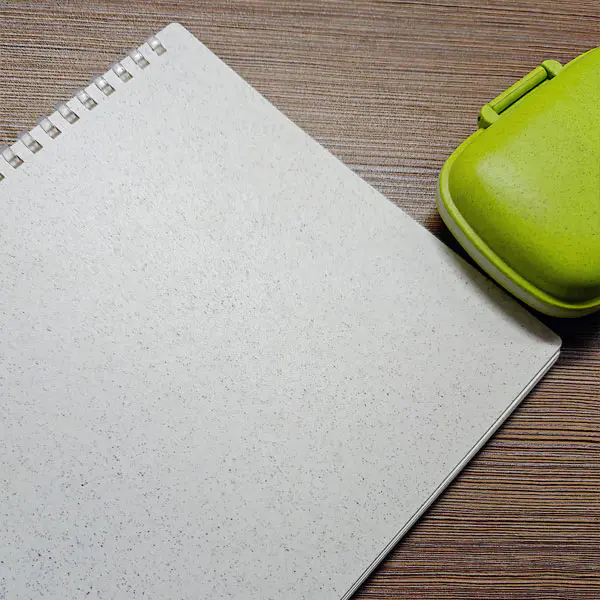

For inquiries about Bio-Based Plastic, Straw Fiber Plastic, Bamboo Fiber Plastic or price list, please leave your email to us and we will be in touch within 24 hours.