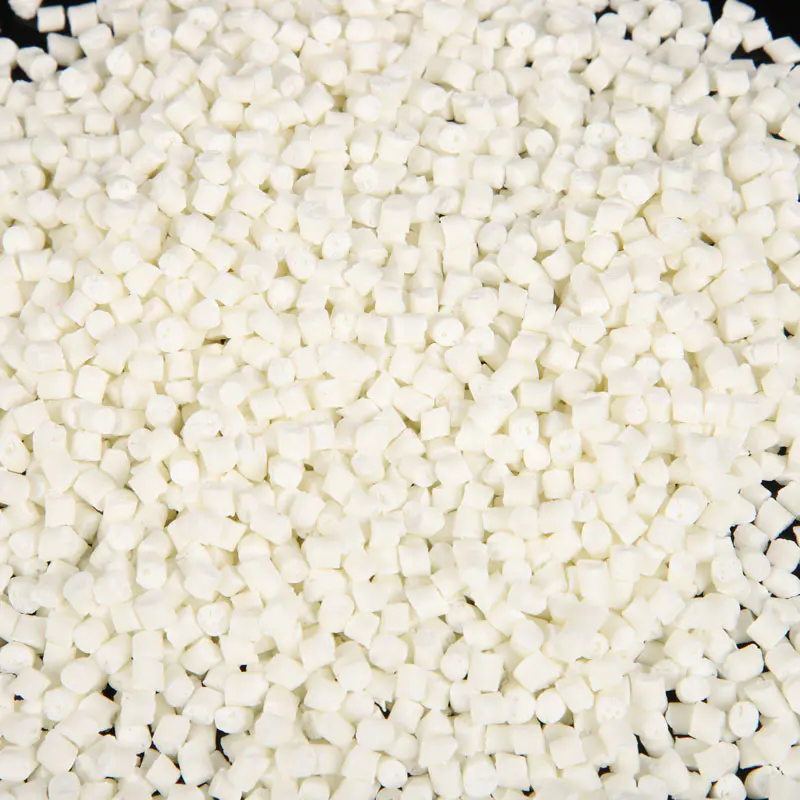

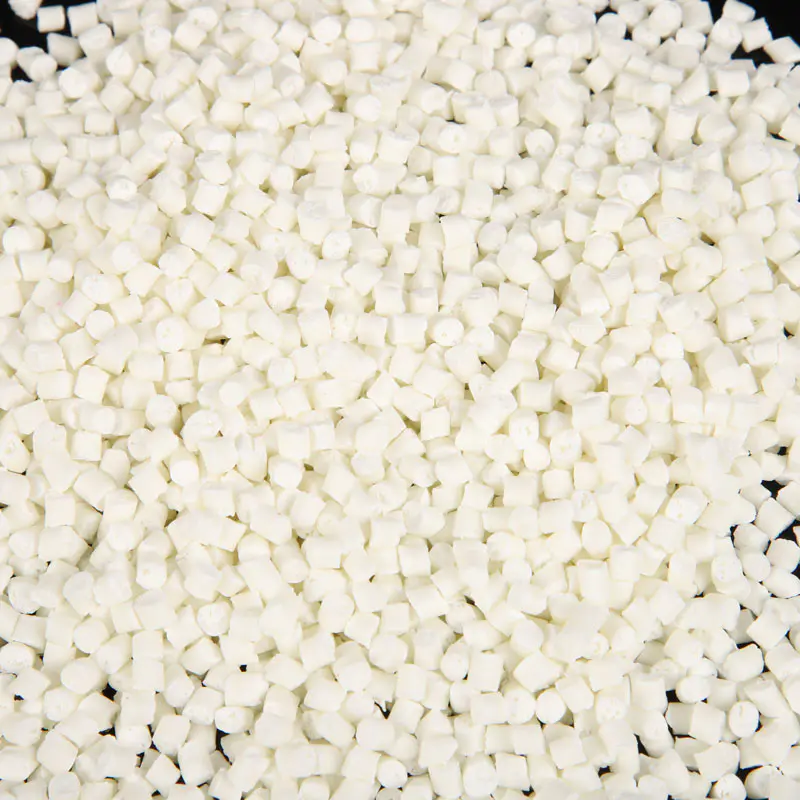

Bio-based Plastic Granules

Brand introduction

Jiangsu Jinhe, in the field of bio-based plastics intensive cultivation, focus on the development and production of bio-based plastic granules. Adhering to the concept of green environmental protection, with advanced technology and rich experience, we have established an excellent brand image in the industry, and are trusted partners of many enterprises.

Product overview

The bio-based plastic granules are made from renewable biological resources by advanced polymerization process. "bio-based plastic granules", as a core product, runs through the key link of the plastic processing industry chain, providing a basic and environmentally friendly raw material choice for the production of various plastic products, and helping various industries to move towards the road of sustainable development.

Product characteristics

(1) Renewable raw materials

Based on rich biomass, such as plant starch, cellulose, etc., these raw materials have the characteristics of sustainable regeneration, reducing the dependence on limited oil resources, reducing the impact on the environment from the source, in line with the global resource recycling and sustainable development strategy requirements.

(2) High particle quality

The particle shape is uniform and regular, the size accuracy is high, and it has good fluidity and dispersion. This makes the subsequent plastic processing process, such as injection molding, extrusion, blow molding and other processes, can be more smooth material transportation and molding operations, to ensure that the quality of the produced plastic products is stable, beautiful appearance, low scrap rate, effectively improve production efficiency and reduce production costs.

(3) Good processing performance

It is highly suitable for a variety of plastic processing equipment and processes, and can easily achieve melting, plasticizing, molding and other processes under conventional processing temperature, pressure and other parameters. Whether it is the manufacture of simple disposable plastic products or complex industrial parts, processing parameters can be flexibly adjusted according to product design requirements, to achieve efficient and accurate production and manufacturing, to meet the diverse needs of different customers.

(4) Excellent degradation performance

In the natural environment or under specific composting conditions, it can quickly start the degradation process, and gradually decompose into harmless water, carbon dioxide and biomass under the action of microorganisms. Its degradation rate is significantly faster than that of traditional plastics, effectively shortening the residence time of plastic waste in the environment, reducing the pollution pressure on soil, water and other ecosystems, and providing a strong material support for solving the problem of plastic waste siege.

(5) The performance is adjustable

The properties of bio-based plastic granules can be flexibly adjusted by adjusting the raw material formula, the type and amount of additives, etc. For example, the addition of reinforcing agents can improve the strength and rigidity of the particles to meet the requirements of mechanical properties in the field of engineering plastics; Adding plasticizer can improve its flexibility and processing flow, which is suitable for the manufacture of soft plastic products; Adding functional additives such as flame retardants and antibacterial agents can give plastic products special functional characteristics and expand their application range.

Application scenarios

(1) Injection molding industry

It is widely used in the production of various injection molding products, such as plastic toys, electronic and electrical shells, automotive interior parts, daily necessities, etc. bio-based plastic granules can quickly melt and fill the mold cavity in the injection molding machine, and the molded product has good surface quality and dimensional accuracy, and has environmental protection and degradable characteristics, which meets the demand of modern consumers for green products, and helps to improve the added value of products and market competitiveness.

(2) Extrusion industry

It can be used for extrusion molding to produce plastic pipes, profiles, films, sheets and other products. In the extrusion process, the bio-based plastic granules can stably pass through the screw extruder to form a continuous uniform melt, and under the action of the mold to shape plastic products of various shapes. For example, the manufacture of environmentally friendly construction drainage pipes, agricultural irrigation pipes, packaging films, decorative profiles, etc., while meeting the performance of products, it reduces the negative impact on the environment and promotes the sustainable development of related industries.

(3) Blow molding industry

Suitable for blow molding process to manufacture hollow plastic products, such as plastic bottles, barrels, cans and other containers. After blow molding of bio-based plastic granules, hollow containers with good wall thickness uniformity and mechanical properties can be obtained, which are used for packaging of food, beverage and daily chemical products. Its environmental protection characteristics enable packaging waste to degrade naturally in the process of treatment, reducing the harm to the environment, and providing a feasible material solution for the green transformation of the packaging industry.

(4) 3D printing industry

With the rapid development of 3D printing technology, bio-based plastic granules have gradually become one of the important choices for 3D printing materials. Its good fluidity and processability enable it to be precisely stacked layer by layer in a 3D printer to create customized products with complex shapes, such as personalized medical devices, creative home accessories, industrial parts prototypes, etc. At the same time, the environmental properties of bio-based plastics provide new directions and opportunities for the sustainable development of the 3D printing industry.

Research and development technology and production strength

(1) Research and development technology

Jiangsu Jinhe has a professional research and development team of bio-based plastics, the team members cover materials science, chemical engineering, polymer physics and other multidisciplinary experts and technicians. Actively carry out industry-university-research cooperation and technical exchanges with domestic and foreign scientific research institutions and industry associations, and jointly explore the cutting-edge technology and innovative application of bio-based plastic granules. Through in-depth research and screening of biological raw materials, combined with advanced polymerization process, modification technology and formula optimization, we have continuously developed new bio-based plastic pellet products with independent intellectual property rights, and made a number of technological breakthroughs and innovations in particle performance improvement, degradation performance regulation and processing process optimization, leading the industry.

(2) Production strength

The company has modern production facilities and advanced production equipment, and the production base is constructed and operated in strict accordance with international quality management system and environmental protection standards. From the pretreatment of raw materials to the synthesis, post-treatment and packaging of plastic particles, each production link uses automated control systems and refined management processes to ensure efficient, stable and accurate production processes. With large-scale production capacity, it can meet the large demand of the market for bio-based plastic granules, and through continuous technological transformation and capacity expansion, constantly improve product quality and production efficiency, reduce production costs, and provide customers with competitive product prices and high-quality after-sales service.

Quality control and testing

A set of perfect quality control and testing system has been established, starting from the source of raw material procurement, strict control of the quality and environmental protection indicators of each batch of raw materials to ensure that the production requirements of bio-based plastic granules are met. In the production process, set up multiple quality inspection processes, the use of advanced testing equipment and analysis methods, The product's physical properties (such as particle size distribution, density, melt flow rate, mechanical properties, etc.), chemical composition (such as biobase content, additive composition, etc.), biodegradation performance (such as degradation rate, degradation product analysis, etc.) and microbial indicators (such as bacteria, mold content, etc.) are comprehensively tested and monitored. For example, particle size distribution is detected by laser particle size analyzer, thermal properties are determined by differential scanning calorimeter (DSC) and thermogravimetric analyzer (TGA), mechanical properties are tested by universal material testing machine, chemical composition and degradation products are analyzed by gas chromatography-mass spectrometry (GC-MS). Microbial culture and detection techniques were used to evaluate microbial indexes. Only products that have passed strict quality inspection and all indicators are in line with industry standards and customer requirements will be allowed to enter the market for sale to provide customers with high-quality and reliable bio-based plastic pellet products.

Procurement and contact information

If you are interested in Jiangsu Jinhe bio-based plastic pellet products, please feel free to contact us.

Contact Number: +86-15861358236

Email: vena@bio-based.cn

Our professional team will be happy to serve you, provide you with detailed product information, quotes and customized solutions, and look forward to working with you to create a green and environmentally friendly plastics industry new future.

- Bio-based Plastic for Recycling

- Bio-based Plastic for Composting

- Bio-based Plastic for Waste Management

- Bio-based Plastic with Slow Release Function

- Bio-based Plastic for Water Treatment

- Bio-based Plastic for Energy Storage

- Bio-based Plastic for Textile Industry

- Pet Toy Bio-Based Plastic

- Bio-based Plastic for Furniture

- UV-resistant Bio-based Plastic

-

Address

Zhai Zhuang Road, Hangji Town, Yangzhou City, Jiangsu Province, China

-

Tel

-

E-mail