Sustainable Bio-based Plastic

Brand introduction

Jiangsu Jinhe specializes in the field of sustainable materials, focusing on the innovation and manufacturing of sustainable bio-based plastics. To protect the earth home as its own responsibility, with deep technical heritage and unremitting exploration spirit, in the industry to establish a green benchmark image.

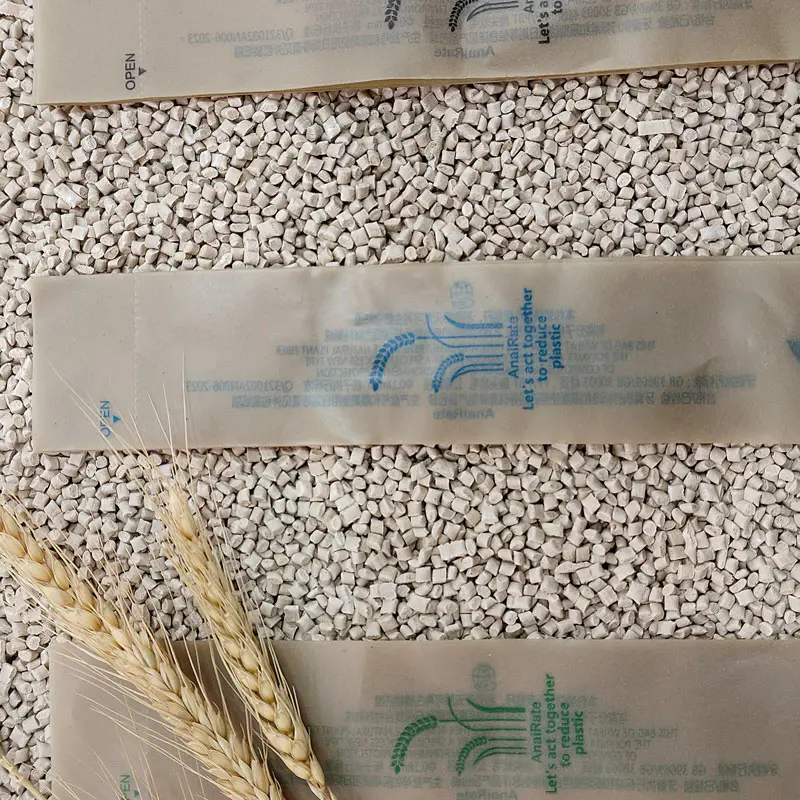

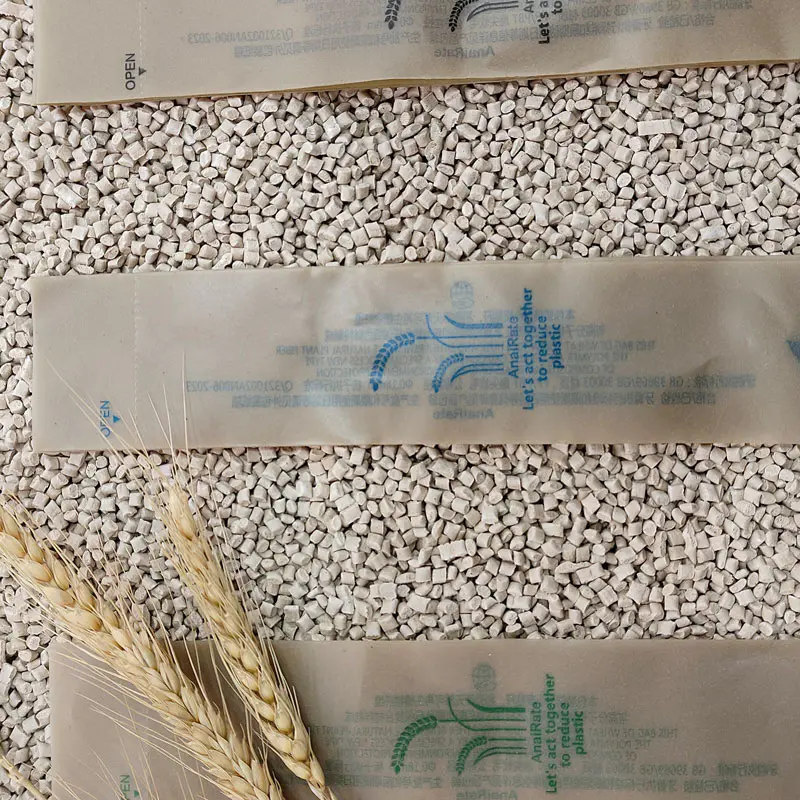

Product overview

This sustainable biobased plastic is based on abundant natural biological resources and converted through advanced and environmentally friendly processes. The core logo of "sustainable biobased plastics" runs through its entire life cycle, from the cultivation and collection of raw materials to the application of product molding, and then to the final degradation cycle, which interprets the concept of sustainable development in an all-round way, and provides new materials with both environmental protection and performance for modern industry and life.

product characteristics

(1) High efficiency biodegradability

Under natural environmental conditions, it can be rapidly catabolized by microorganisms, and the degradation process is efficient and thorough, and eventually converted into natural substances such as water, carbon dioxide and biomass, without harmful residues. Whether it is the microbial flora in the soil environment or the specific microorganisms in the water environment, it can effectively act on the plastic, greatly shortening its existence cycle in the environment, and reducing the heavy burden of plastic waste on the ecosystem for a long time.

(2) Excellent physical and mechanical properties

With excellent strength and toughness, it can withstand greater external impact, stretching and bending without breaking or excessive deformation. Its good mechanical properties can meet the needs of a wide range of application scenarios, from the structural components in industrial manufacturing to the packaging materials of daily supplies, can provide reliable physical support and protection, to ensure the safety and stability of the product during use, and effectively extend the service life of the product.

(3) Flexible and diverse processing

Perfect for a variety of plastic processing processes, including but not limited to injection molding, extrusion, blow molding, thermoforming, and 3D printing and other emerging processes. This broad process compatibility allows it to accurately manufacture plastic products with complex shapes and specifications according to different design needs and production scales. Whether it is large-scale industrial production of standard parts, or personalized customized niche products, can be easily achieved by choosing the right processing technology, greatly expanding the application range of products and design freedom.

(4) Good thermal stability

It can maintain stable physical and chemical properties in a wide temperature range, and is not easy to soften, deform or decompose due to temperature changes. Whether it is industrial processing under high temperature environment, or storage and use scenarios under low temperature conditions, the sustainable bio-based plastic can stably play its performance advantages, providing a solid guarantee for the application of products in different thermal environments, effectively avoiding product quality problems and safety hazards caused by thermal effects.

(5) Customizable and functional

Multi-dimensional customized design and functional addition can be carried out according to customers' specific application needs and market preferences. In terms of color, transparency, surface texture and other appearance characteristics can be customized to meet the unique design requirements of different brands and products; At the same time, it can also be added by adding specific functional additives, such as flame retardants, antibacterial agents, antistatic agents, etc., to give products additional functional characteristics, further improve the added value of products and market competitiveness, to adapt to diversified market demand and industry standards.

Application scenarios

(1) Packaging application

It is widely used in food, beverage, cosmetics, medicine and other product packaging fields. As a packaging film, container, bottle cap and other components, it can effectively protect the product from physical damage, block oxygen and water vapor to extend the shelf life, and can rely on its sustainable characteristics, achieve rapid degradation after product consumption, reduce packaging waste pollution to the environment, in line with the growing demand of modern consumers for green packaging and environmental protection expectations.

(2) Agriculture

It is used to manufacture agricultural plastic film, seedling container, irrigation pipe, greenhouse skeleton and other agricultural production materials. Agricultural mulching film can play an important role in the early growth of crops, such as heat preservation, moisture, weed control, and self-degradation after the end of the growing season, so as to avoid long-term damage to soil quality and ecological environment caused by traditional plastic mulching film residues. Seedling containers and irrigation pipes can improve agricultural production efficiency, reduce resource consumption and environmental pollution in the agricultural production process, and help the sustainable development of agriculture.

(3) Consumer electronics and electrical appliances

Excellent performance in the shell manufacturing of consumer electronic devices such as mobile phones, computers, tablets, and internal structural parts and shell applications of electrical products. Its good mechanical properties can provide reliable physical protection for electronic equipment to resist collision and drop in daily use; At the same time, its environmental degradable characteristics meet the increasingly strict environmental regulations and green supply chain requirements of the electronic and electrical industry, which helps electronic and electrical enterprises to enhance their brand image and social responsibility, and promote the green upgrade of the entire industry.

(4) Automobile manufacturing

It can be used in the manufacture of automotive interior components such as instrument panel, door panel, seat armrest, center console decoration, etc., as well as some non-critical structural components. It can not only meet the strict requirements of the material texture, comfort and aesthetics of the automotive interior, but also reduce the overall weight of the vehicle through its lightweight characteristics, thereby improving fuel economy and reducing exhaust emissions. In addition, the environmental properties of sustainable bio-based plastics are highly compatible with the sustainable development strategy of the automotive industry, providing a strong material support for car manufacturers to create green automotive products.

(5) Building and home decoration

In the field of construction, it can be used to manufacture exterior wall decorative panels, interior decorative lines, ceiling materials, doors and Windows sealing strips and other components. Its good weather resistance, mechanical properties and aesthetic properties can meet the diversified needs of building decoration, and can achieve environmental degradation after the end of the building service life, reducing the pressure of construction waste on the environment; In home decoration, it can be used in furniture manufacturing, home accessories, curtain rods and other products to add green environmental protection elements to home life and create a healthy and comfortable living environment.

Research and development technology and production strength

(1) Research and development technology

Jiangsu Jinhe has a top research and development team composed of interdisciplinary experts, covering materials science, biology, chemical engineering, environmental science and other fields. The team has been committed to the basic research and application development of sustainable bio-based plastics for a long time, and has established in-depth industry-university-research cooperation with well-known scientific research institutions and universities at home and abroad. Through in-depth mining and screening of biological resources, combined with advanced gene editing technology, biological fermentation technology, chemical synthesis and modification technology, we constantly explore the molecular structure design and synthesis path of new bio-based plastics, and successfully develop a series of sustainable bio-based plastic products with independent intellectual property rights and excellent performance. And in the biodegradation mechanism, high-performance material formulation, functional additives and other key technical fields have made a number of major breakthroughs and innovations.

(2) Production strength

The company has a modern, large-scale production base, equipped with the international leading level of production equipment and automation control system. From the pretreatment, fermentation and extraction of biological raw materials to the synthesis, modification and molding of plastic particles, each production link strictly follows the requirements of international quality management system and environmental protection standards. The production workshop adopts intelligent management mode to realize efficient and precise control of the production process and optimal allocation of resources, and has the ability to produce various sustainable bio-based plastic products on a large scale and stably. At the same time, the company pays attention to energy saving and emission reduction in the production process and the development of circular economy, through the introduction of advanced waste heat recovery, waste gas treatment and waste water recycling technology, to minimize the impact of the production process on the environment, and achieve a win-win situation of economic and environmental benefits.

Quality control and testing

A comprehensive and multi-level quality control and testing system has been established, starting from the source control of biological raw materials to ensure the quality stability and sustainability of each batch of raw materials. In the production process, a number of strict quality inspection processes are set up, and advanced testing equipment and analysis methods are used to monitor and accurately analyze key indicators such as physical properties, chemical composition, biodegradation performance, microbial indicators and thermal stability of products in real time. For example, the use of high-precision material testing machine to detect mechanical properties, the use of gas chromatoc-mass spectrometry to analyze chemical composition, with the help of special biodegradation testing equipment to assess the rate and degree of degradation, through microbial culture and detection technology to monitor microbial indicators. Only products that have passed strict quality inspection and all indicators are in line with international standards and customer specific requirements will be allowed to enter the market for sale, providing high-quality, reliable and sustainable bio-based plastic products to customers around the world.

Procurement and contact information

If you are interested in Jiangsu Jinhe's sustainable bio-based plastic products, please feel free to contact us.

Contact Number: +86-15861358236

Email: vena@bio-based.cn

Our professional team will be happy to serve you, provide you with detailed product information, quotes and customized solutions, and look forward to working with you to create a green and sustainable future.

- Bio-based Plastic Reinforcement

- Sustainable Bio-Based Agricultural Film

- High Strength Bio-based Plastic

- Tough Bio-based Plastic

- Low Density Bio-based Plastic

- High Heat Resistant Bio-based Plastic

- Chemically Resistant Bio-based Plastic

- Antimicrobial Bio-based Plastic

- Antistatic Bio-based Plastic

- Bio-based Plastic for Livestock Farming

-

Address

Zhai Zhuang Road, Hangji Town, Yangzhou City, Jiangsu Province, China

-

Tel

-

E-mail